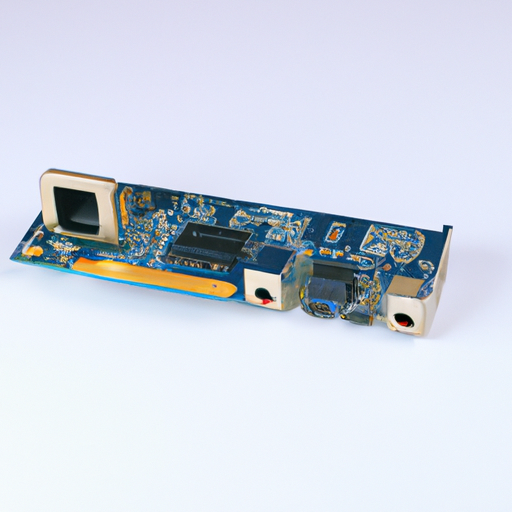

A card edge connector is a type of electrical connector that is commonly used to connect printed circuit boards (PCBs) to other devices or PCBs. It is designed to provide a secure and reliable connection between the PCB and the external device, allowing for the transfer of electrical signals and power.

1. Contact Pins: Contact pins are the primary components of a card edge connector. They are responsible for establishing electrical connections between the PCB and the external device. These pins are usually made of high-quality materials such as copper alloy or phosphor bronze to ensure good conductivity and durability. Contact pins can be either male or female, depending on the design of the connector.

2. Insulator: The insulator is a non-conductive material that surrounds the contact pins, providing electrical insulation and mechanical support. It helps to prevent short circuits and ensures proper alignment of the pins during insertion and removal of the PCB. Insulators are typically made of thermoplastic materials like nylon or polyester, which offer excellent dielectric properties and mechanical strength.

3. Housing: The housing is an outer shell that encloses the contact pins and insulator, providing protection and stability to the connector. It is usually made of plastic or metal, depending on the application requirements. The housing may also include features like locking mechanisms or latches to secure the connector in place and prevent accidental disconnection.

4. Grounding: Many card edge connectors include grounding features to ensure proper grounding of the PCB. These can include grounding clips or pins that establish a reliable electrical connection between the PCB and the external device's ground plane. Grounding is crucial for minimizing electromagnetic interference (EMI) and maintaining signal integrity.

5. Shielding: In some high-frequency applications, card edge connectors may incorporate shielding features to minimize EMI and ensure signal integrity. Shielding can be achieved through the use of metal shields or conductive coatings on the connector's housing. These shields help to prevent external electromagnetic signals from interfering with the transmitted signals.

6. Mounting Options: Card edge connectors can be mounted on PCBs in various ways, depending on the application and design requirements. Common mounting options include through-hole mounting, surface mount technology (SMT), or press-fit technology. Through-hole mounting involves inserting the connector's pins into pre-drilled holes on the PCB and soldering them in place. SMT connectors are soldered directly onto the surface of the PCB, while press-fit connectors are pressed into plated through-holes without the need for soldering.

7. Additional Features: Card edge connectors may also include additional features to enhance their functionality and usability. These can include polarization features to ensure proper alignment during insertion, keying options to prevent incorrect connections, or hot-plug capabilities for easy insertion and removal of the PCB while the system is powered.

In conclusion, a card edge connector is a vital component in electronic systems, enabling the reliable connection between PCBs and external devices. Its key components include contact pins, insulators, housing, grounding, shielding, mounting options, and additional features. Understanding these components and their functions is essential for selecting the right card edge connector for specific applications, ensuring optimal performance and reliability.

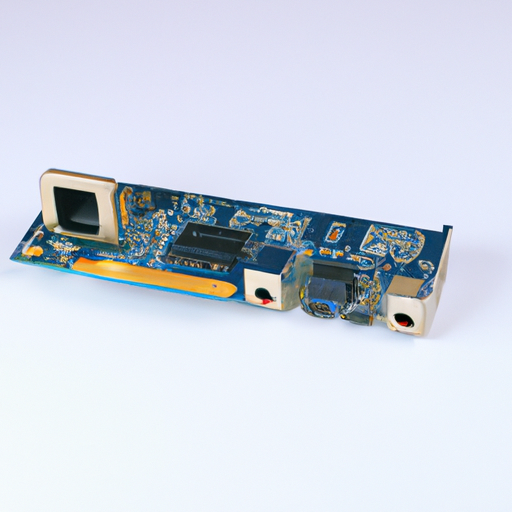

A card edge connector is a type of electrical connector that is commonly used to connect printed circuit boards (PCBs) to other devices or PCBs. It is designed to provide a secure and reliable connection between the PCB and the external device, allowing for the transfer of electrical signals and power.

1. Contact Pins: Contact pins are the primary components of a card edge connector. They are responsible for establishing electrical connections between the PCB and the external device. These pins are usually made of high-quality materials such as copper alloy or phosphor bronze to ensure good conductivity and durability. Contact pins can be either male or female, depending on the design of the connector.

2. Insulator: The insulator is a non-conductive material that surrounds the contact pins, providing electrical insulation and mechanical support. It helps to prevent short circuits and ensures proper alignment of the pins during insertion and removal of the PCB. Insulators are typically made of thermoplastic materials like nylon or polyester, which offer excellent dielectric properties and mechanical strength.

3. Housing: The housing is an outer shell that encloses the contact pins and insulator, providing protection and stability to the connector. It is usually made of plastic or metal, depending on the application requirements. The housing may also include features like locking mechanisms or latches to secure the connector in place and prevent accidental disconnection.

4. Grounding: Many card edge connectors include grounding features to ensure proper grounding of the PCB. These can include grounding clips or pins that establish a reliable electrical connection between the PCB and the external device's ground plane. Grounding is crucial for minimizing electromagnetic interference (EMI) and maintaining signal integrity.

5. Shielding: In some high-frequency applications, card edge connectors may incorporate shielding features to minimize EMI and ensure signal integrity. Shielding can be achieved through the use of metal shields or conductive coatings on the connector's housing. These shields help to prevent external electromagnetic signals from interfering with the transmitted signals.

6. Mounting Options: Card edge connectors can be mounted on PCBs in various ways, depending on the application and design requirements. Common mounting options include through-hole mounting, surface mount technology (SMT), or press-fit technology. Through-hole mounting involves inserting the connector's pins into pre-drilled holes on the PCB and soldering them in place. SMT connectors are soldered directly onto the surface of the PCB, while press-fit connectors are pressed into plated through-holes without the need for soldering.

7. Additional Features: Card edge connectors may also include additional features to enhance their functionality and usability. These can include polarization features to ensure proper alignment during insertion, keying options to prevent incorrect connections, or hot-plug capabilities for easy insertion and removal of the PCB while the system is powered.

In conclusion, a card edge connector is a vital component in electronic systems, enabling the reliable connection between PCBs and external devices. Its key components include contact pins, insulators, housing, grounding, shielding, mounting options, and additional features. Understanding these components and their functions is essential for selecting the right card edge connector for specific applications, ensuring optimal performance and reliability.