Title: Exploring the Versatile Product Features of Welded Tape Connectors

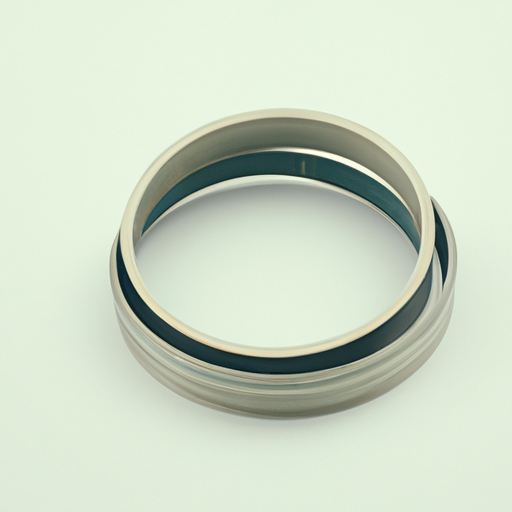

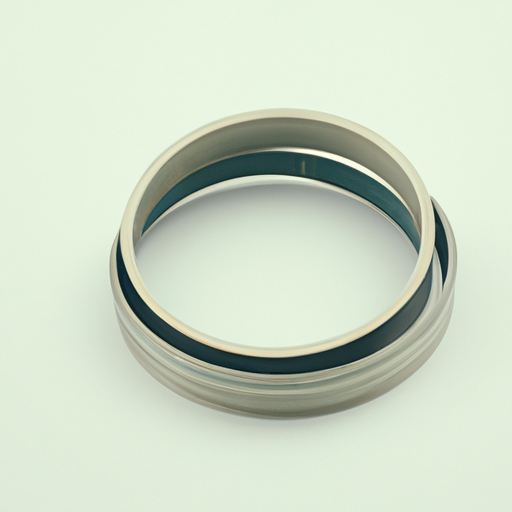

1. Robust Construction (150 words) One of the primary features of welded tape connectors is their robust construction. These connectors are typically made from high-quality materials such as stainless steel or aluminum, ensuring durability and longevity. The welding process used in their production creates a strong bond between the connector and the materials it joins, making it resistant to mechanical stress and environmental factors.

2. Versatile Applications (200 words) Welded tape connectors find applications in a wide range of industries due to their versatility. In the construction sector, they are commonly used to join structural elements, reinforcing bars, and steel plates. Their ability to withstand heavy loads and extreme conditions makes them ideal for infrastructure projects such as bridges, tunnels, and high-rise buildings.

In the automotive industry, welded tape connectors play a crucial role in connecting various components, including exhaust systems, chassis, and body panels. Their resistance to vibrations and high temperatures ensures the integrity and safety of the vehicle.

Moreover, in the electronics sector, these connectors are utilized for joining circuit boards, ensuring reliable electrical connections. Their compact size and ability to withstand thermal stress make them suitable for applications in consumer electronics, telecommunications, and aerospace industries.

3. Resistance to Environmental Factors (200 words) Welded tape connectors are designed to withstand a wide range of environmental factors, making them suitable for both indoor and outdoor applications. They exhibit excellent resistance to corrosion, ensuring their longevity even in harsh environments such as coastal areas or chemical plants. This resistance is particularly important in industries where exposure to moisture, chemicals, or extreme temperatures is common.

Additionally, welded tape connectors are often coated with protective layers, such as zinc or epoxy, to enhance their resistance to environmental factors. These coatings provide an extra layer of protection against rust, oxidation, and other forms of degradation, further extending the lifespan of the connectors.

4. Easy Installation and Maintenance (150 words) Another notable feature of welded tape connectors is their ease of installation and maintenance. These connectors are designed to be user-friendly, allowing for quick and efficient installation without the need for specialized tools or extensive training. This feature significantly reduces labor costs and project timelines.

Furthermore, maintenance requirements for welded tape connectors are minimal. Their robust construction and resistance to environmental factors mean that they can withstand prolonged use without the need for frequent repairs or replacements. This aspect makes them a cost-effective solution for industries that require long-term reliability and durability.

Conclusion (100 words) Welded tape connectors offer a multitude of product features that make them indispensable in various industries. Their robust construction, versatile applications, resistance to environmental factors, and ease of installation and maintenance make them a reliable choice for professionals in construction, automotive, and electronics sectors. As technology advances and industries evolve, the demand for these connectors is expected to grow, further emphasizing their importance in modern engineering and manufacturing processes.

Title: Exploring the Versatile Product Features of Welded Tape Connectors

1. Robust Construction (150 words) One of the primary features of welded tape connectors is their robust construction. These connectors are typically made from high-quality materials such as stainless steel or aluminum, ensuring durability and longevity. The welding process used in their production creates a strong bond between the connector and the materials it joins, making it resistant to mechanical stress and environmental factors.

2. Versatile Applications (200 words) Welded tape connectors find applications in a wide range of industries due to their versatility. In the construction sector, they are commonly used to join structural elements, reinforcing bars, and steel plates. Their ability to withstand heavy loads and extreme conditions makes them ideal for infrastructure projects such as bridges, tunnels, and high-rise buildings.

In the automotive industry, welded tape connectors play a crucial role in connecting various components, including exhaust systems, chassis, and body panels. Their resistance to vibrations and high temperatures ensures the integrity and safety of the vehicle.

Moreover, in the electronics sector, these connectors are utilized for joining circuit boards, ensuring reliable electrical connections. Their compact size and ability to withstand thermal stress make them suitable for applications in consumer electronics, telecommunications, and aerospace industries.

3. Resistance to Environmental Factors (200 words) Welded tape connectors are designed to withstand a wide range of environmental factors, making them suitable for both indoor and outdoor applications. They exhibit excellent resistance to corrosion, ensuring their longevity even in harsh environments such as coastal areas or chemical plants. This resistance is particularly important in industries where exposure to moisture, chemicals, or extreme temperatures is common.

Additionally, welded tape connectors are often coated with protective layers, such as zinc or epoxy, to enhance their resistance to environmental factors. These coatings provide an extra layer of protection against rust, oxidation, and other forms of degradation, further extending the lifespan of the connectors.

4. Easy Installation and Maintenance (150 words) Another notable feature of welded tape connectors is their ease of installation and maintenance. These connectors are designed to be user-friendly, allowing for quick and efficient installation without the need for specialized tools or extensive training. This feature significantly reduces labor costs and project timelines.

Furthermore, maintenance requirements for welded tape connectors are minimal. Their robust construction and resistance to environmental factors mean that they can withstand prolonged use without the need for frequent repairs or replacements. This aspect makes them a cost-effective solution for industries that require long-term reliability and durability.

Conclusion (100 words) Welded tape connectors offer a multitude of product features that make them indispensable in various industries. Their robust construction, versatile applications, resistance to environmental factors, and ease of installation and maintenance make them a reliable choice for professionals in construction, automotive, and electronics sectors. As technology advances and industries evolve, the demand for these connectors is expected to grow, further emphasizing their importance in modern engineering and manufacturing processes.