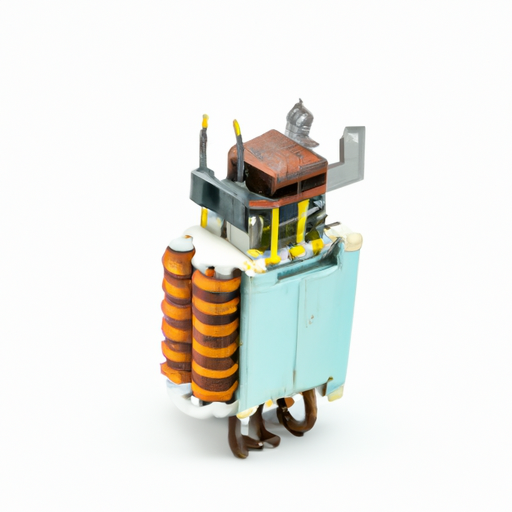

Linear Variable Differential Transformers (LVDTs) are a type of transformer used to convert mechanical motion into an electrical signal. They are commonly used in a variety of industrial and scientific applications where precise measurements of linear displacement are required. LVDTs are known for their high accuracy, reliability, and durability, making them a popular choice for many different types of measurement and control systems.

One of the key advantages of LVDTs is their high accuracy and linearity. LVDTs are capable of providing measurements with resolutions as low as a few micrometers, making them ideal for applications where precise positioning or control is required. Additionally, LVDTs have a very linear response over a wide range of displacements, allowing for accurate measurements even at extreme positions.

Another advantage of LVDTs is their reliability and durability. LVDTs are known for their long-term stability and resistance to environmental factors such as temperature, humidity, and vibration. This makes them well-suited for use in harsh industrial environments where other types of sensors may be prone to failure.

LVDTs are also easy to install and maintain. They do not require any physical contact between the core and the coil assembly, which eliminates the need for regular calibration or adjustment. Additionally, LVDTs have a simple and robust design, which minimizes the risk of mechanical failure.

LVDTs are used in a wide range of applications across various industries. In the aerospace industry, LVDTs are used to measure the position of aircraft control surfaces, landing gear, and engine components. In the automotive industry, LVDTs are used to monitor the position of valves, pistons, and other moving parts in engines and transmissions. In the medical field, LVDTs are used in medical devices such as infusion pumps, ventilators, and robotic surgery systems.

Overall, LVDTs are a versatile and reliable technology that provides accurate and precise measurements of linear displacement. Their high accuracy, linearity, reliability, and durability make them an ideal choice for a wide range of industrial and scientific applications. Whether used in aerospace, automotive, medical, or other industries, LVDTs play a crucial role in ensuring the smooth and efficient operation of complex systems.

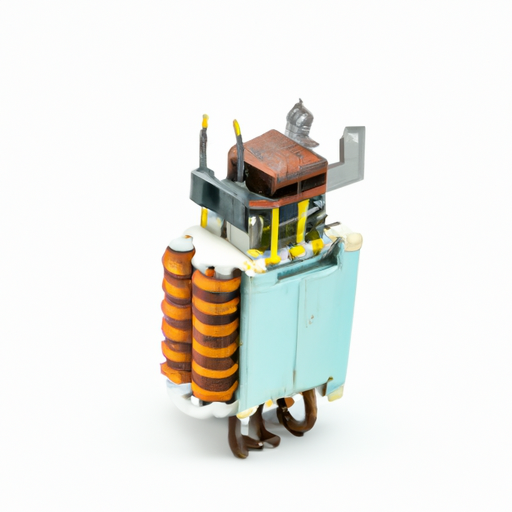

Linear Variable Differential Transformers (LVDTs) are a type of transformer used to convert mechanical motion into an electrical signal. They are commonly used in a variety of industrial and scientific applications where precise measurements of linear displacement are required. LVDTs are known for their high accuracy, reliability, and durability, making them a popular choice for many different types of measurement and control systems.

One of the key advantages of LVDTs is their high accuracy and linearity. LVDTs are capable of providing measurements with resolutions as low as a few micrometers, making them ideal for applications where precise positioning or control is required. Additionally, LVDTs have a very linear response over a wide range of displacements, allowing for accurate measurements even at extreme positions.

Another advantage of LVDTs is their reliability and durability. LVDTs are known for their long-term stability and resistance to environmental factors such as temperature, humidity, and vibration. This makes them well-suited for use in harsh industrial environments where other types of sensors may be prone to failure.

LVDTs are also easy to install and maintain. They do not require any physical contact between the core and the coil assembly, which eliminates the need for regular calibration or adjustment. Additionally, LVDTs have a simple and robust design, which minimizes the risk of mechanical failure.

LVDTs are used in a wide range of applications across various industries. In the aerospace industry, LVDTs are used to measure the position of aircraft control surfaces, landing gear, and engine components. In the automotive industry, LVDTs are used to monitor the position of valves, pistons, and other moving parts in engines and transmissions. In the medical field, LVDTs are used in medical devices such as infusion pumps, ventilators, and robotic surgery systems.

Overall, LVDTs are a versatile and reliable technology that provides accurate and precise measurements of linear displacement. Their high accuracy, linearity, reliability, and durability make them an ideal choice for a wide range of industrial and scientific applications. Whether used in aerospace, automotive, medical, or other industries, LVDTs play a crucial role in ensuring the smooth and efficient operation of complex systems.