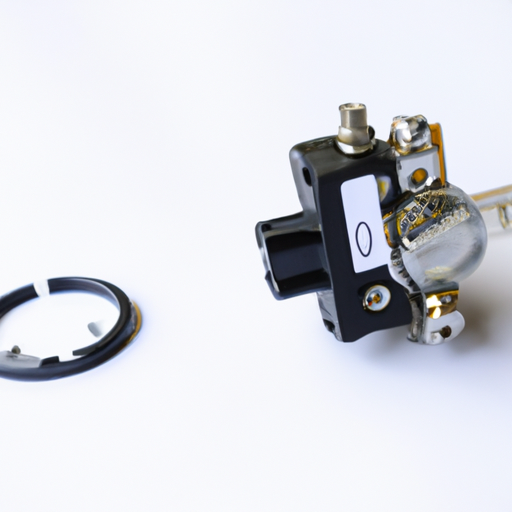

A vibration sensor is a type of sensor that is used to detect and measure vibrations in various objects and structures. These sensors are commonly used in a wide range of applications, including industrial machinery, automotive systems, aerospace technology, and even consumer electronics. Vibration sensors are essential for monitoring the health and performance of equipment, as well as for detecting potential issues before they escalate into more serious problems.

Accelerometers are one of the most widely used types of vibration sensors. These sensors measure the acceleration of an object in response to vibrations, and can provide valuable information about the frequency, amplitude, and direction of the vibrations. Accelerometers are typically used in applications where high sensitivity and accuracy are required, such as in the aerospace and automotive industries.

Piezoelectric sensors are another popular type of vibration sensor. These sensors generate an electrical charge in response to mechanical stress, such as vibrations or pressure. Piezoelectric sensors are known for their high sensitivity and fast response times, making them ideal for applications where real-time monitoring is essential.

Velocity sensors are another type of vibration sensor that measures the velocity of an object in response to vibrations. These sensors are often used in applications where the speed and direction of the vibrations are critical, such as in rotating machinery or structural monitoring.

In addition to these common types of vibration sensors, there are also specialized sensors available for specific applications. For example, seismic sensors are used to detect and measure seismic activity, while tilt sensors are used to monitor the inclination or tilt of an object.

The importance of vibration sensors in various industries cannot be overstated. These sensors play a crucial role in ensuring the safety, reliability, and efficiency of equipment and structures. By monitoring vibrations, engineers and technicians can identify potential issues before they lead to costly downtime or catastrophic failures.

In the industrial sector, vibration sensors are used to monitor the health and performance of machinery and equipment. By detecting abnormal vibrations, these sensors can help prevent equipment failures and optimize maintenance schedules. For example, in the manufacturing industry, vibration sensors are used to monitor the condition of motors, pumps, and other critical components to ensure smooth operation and minimize downtime.

In the automotive industry, vibration sensors are used to monitor the performance of vehicles and detect potential issues with the engine, suspension, or other components. By analyzing the vibrations generated by the vehicle, engineers can identify problems early on and take corrective action before they escalate into more serious issues.

In the aerospace industry, vibration sensors are used to monitor the structural integrity of aircraft and spacecraft. These sensors are essential for detecting fatigue, cracks, and other signs of wear and tear that could compromise the safety of the vehicle. By continuously monitoring vibrations, engineers can ensure that aircraft and spacecraft are in optimal condition for flight.

In the consumer electronics industry, vibration sensors are used in a wide range of devices, such as smartphones, tablets, and gaming consoles. These sensors are used to detect gestures, taps, and other interactions with the device, providing a more intuitive and responsive user experience.

Overall, vibration sensors are essential tools for monitoring and analyzing vibrations in various objects and structures. These sensors play a crucial role in ensuring the safety, reliability, and efficiency of equipment and systems in a wide range of industries. By detecting and measuring vibrations, engineers and technicians can identify potential issues early on and take corrective action to prevent costly downtime and failures.

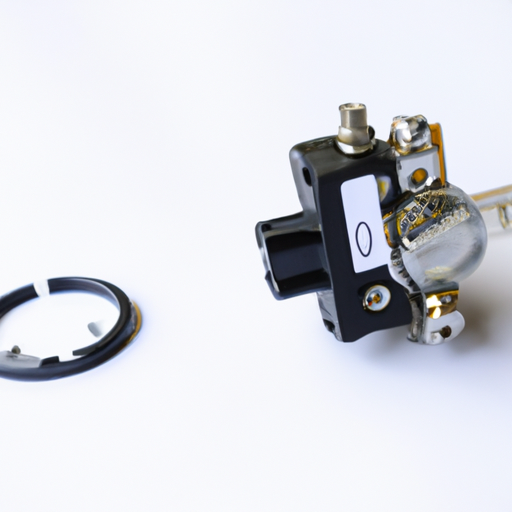

A vibration sensor is a type of sensor that is used to detect and measure vibrations in various objects and structures. These sensors are commonly used in a wide range of applications, including industrial machinery, automotive systems, aerospace technology, and even consumer electronics. Vibration sensors are essential for monitoring the health and performance of equipment, as well as for detecting potential issues before they escalate into more serious problems.

Accelerometers are one of the most widely used types of vibration sensors. These sensors measure the acceleration of an object in response to vibrations, and can provide valuable information about the frequency, amplitude, and direction of the vibrations. Accelerometers are typically used in applications where high sensitivity and accuracy are required, such as in the aerospace and automotive industries.

Piezoelectric sensors are another popular type of vibration sensor. These sensors generate an electrical charge in response to mechanical stress, such as vibrations or pressure. Piezoelectric sensors are known for their high sensitivity and fast response times, making them ideal for applications where real-time monitoring is essential.

Velocity sensors are another type of vibration sensor that measures the velocity of an object in response to vibrations. These sensors are often used in applications where the speed and direction of the vibrations are critical, such as in rotating machinery or structural monitoring.

In addition to these common types of vibration sensors, there are also specialized sensors available for specific applications. For example, seismic sensors are used to detect and measure seismic activity, while tilt sensors are used to monitor the inclination or tilt of an object.

The importance of vibration sensors in various industries cannot be overstated. These sensors play a crucial role in ensuring the safety, reliability, and efficiency of equipment and structures. By monitoring vibrations, engineers and technicians can identify potential issues before they lead to costly downtime or catastrophic failures.

In the industrial sector, vibration sensors are used to monitor the health and performance of machinery and equipment. By detecting abnormal vibrations, these sensors can help prevent equipment failures and optimize maintenance schedules. For example, in the manufacturing industry, vibration sensors are used to monitor the condition of motors, pumps, and other critical components to ensure smooth operation and minimize downtime.

In the automotive industry, vibration sensors are used to monitor the performance of vehicles and detect potential issues with the engine, suspension, or other components. By analyzing the vibrations generated by the vehicle, engineers can identify problems early on and take corrective action before they escalate into more serious issues.

In the aerospace industry, vibration sensors are used to monitor the structural integrity of aircraft and spacecraft. These sensors are essential for detecting fatigue, cracks, and other signs of wear and tear that could compromise the safety of the vehicle. By continuously monitoring vibrations, engineers can ensure that aircraft and spacecraft are in optimal condition for flight.

In the consumer electronics industry, vibration sensors are used in a wide range of devices, such as smartphones, tablets, and gaming consoles. These sensors are used to detect gestures, taps, and other interactions with the device, providing a more intuitive and responsive user experience.

Overall, vibration sensors are essential tools for monitoring and analyzing vibrations in various objects and structures. These sensors play a crucial role in ensuring the safety, reliability, and efficiency of equipment and systems in a wide range of industries. By detecting and measuring vibrations, engineers and technicians can identify potential issues early on and take corrective action to prevent costly downtime and failures.