The wet sensor sensor is a crucial component in various industries, including agriculture, environmental monitoring, and industrial applications. This sensor is designed to detect the presence of moisture or water in a particular environment, providing valuable data for decision-making and control purposes. In this article, we will explore the components and modules that make up a wet sensor sensor, as well as its applications and benefits.

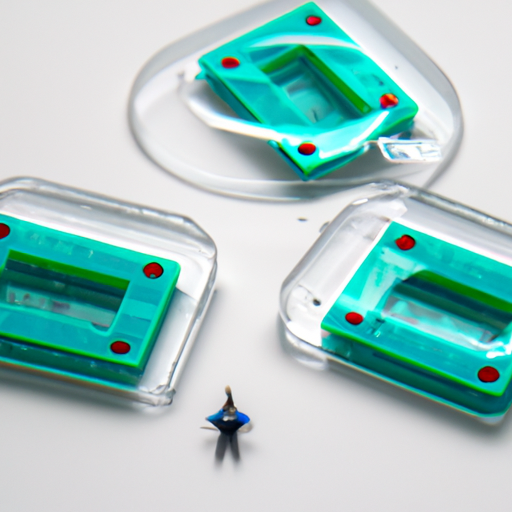

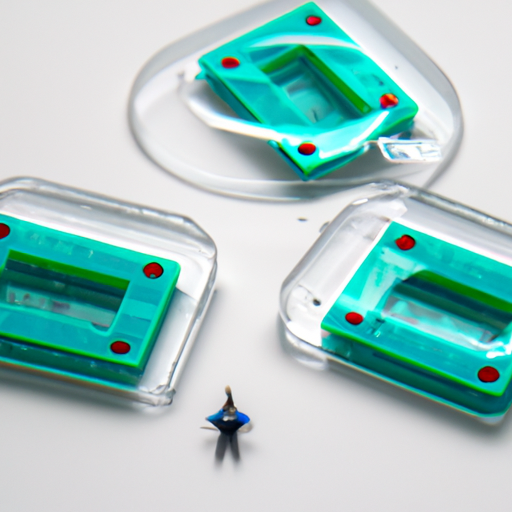

1. Moisture Sensor: The core component of a wet sensor sensor is the moisture sensor itself. This sensor is typically made up of two electrodes that measure the electrical conductivity of the surrounding medium. When moisture or water is present, the conductivity of the medium increases, allowing the sensor to detect the presence of moisture.

2. Microcontroller: The microcontroller is responsible for processing the data collected by the moisture sensor and converting it into a readable format. This component is essential for controlling the sensor's operation and transmitting the data to a monitoring system or display.

3. Transmitter: In some cases, a wet sensor sensor may include a transmitter module that allows the sensor to wirelessly transmit data to a remote monitoring system. This feature is particularly useful in applications where the sensor is located in a hard-to-reach or hazardous environment.

4. Power Supply: A power supply module is required to provide the necessary energy for the sensor to operate. This can be in the form of batteries, solar panels, or a wired power source, depending on the specific requirements of the application.

5. Housing: The housing of the wet sensor sensor is designed to protect the internal components from environmental factors such as moisture, dust, and temperature fluctuations. The housing is typically made of durable materials such as plastic or metal to ensure the sensor's longevity and reliability.

Modules of a Wet Sensor Sensor:

1. Data Logging Module: Some wet sensor sensors may include a data logging module that allows the sensor to store data internally for later retrieval and analysis. This feature is particularly useful in applications where real-time monitoring is not required, or where data transmission is intermittent.

2. Alarm Module: An alarm module can be integrated into a wet sensor sensor to alert users when a certain threshold of moisture or water is detected. This feature is essential in applications where immediate action is required to prevent damage or safety hazards.

3. Calibration Module: A calibration module is used to calibrate the sensor periodically to ensure accurate and reliable measurements. This module allows users to adjust the sensor's sensitivity and accuracy based on the specific requirements of the application.

4. Communication Module: A communication module enables the wet sensor sensor to communicate with other devices or systems, such as a central monitoring station or a smartphone app. This feature allows users to access real-time data and receive alerts remotely.

Applications of Wet Sensor Sensors:

1. Agriculture: Wet sensor sensors are commonly used in agriculture to monitor soil moisture levels and optimize irrigation practices. By accurately measuring the moisture content of the soil, farmers can ensure that crops receive the right amount of water, leading to improved yields and reduced water wastage.

2. Environmental Monitoring: Wet sensor sensors are also used in environmental monitoring applications to track water levels in rivers, lakes, and reservoirs. This data is essential for assessing water quality, predicting floods, and managing water resources effectively.

3. Industrial Applications: In industrial settings, wet sensor sensors are used to detect leaks, spills, and condensation in equipment and facilities. By monitoring moisture levels in critical areas, companies can prevent equipment failures, reduce downtime, and ensure workplace safety.

Benefits of Wet Sensor Sensors:

1. Improved Efficiency: Wet sensor sensors help optimize water usage in agriculture and other industries, leading to cost savings and environmental benefits. By providing real-time data on moisture levels, these sensors enable users to make informed decisions and adjust their practices accordingly.

2. Preventive Maintenance: By detecting moisture or water early on, wet sensor sensors can help prevent equipment failures and costly repairs. This proactive approach to maintenance can extend the lifespan of equipment and reduce downtime, ultimately saving time and money.

3. Remote Monitoring: Wet sensor sensors with wireless communication capabilities allow users to monitor moisture levels from a distance, enabling timely intervention and response. This feature is particularly useful in large-scale operations or remote locations where regular on-site inspections may not be feasible.

In conclusion, the wet sensor sensor is a versatile and essential component in various industries, offering valuable insights into moisture levels and water presence. By understanding the components and modules that make up a wet sensor sensor, as well as its applications and benefits, users can harness the power of this technology to improve efficiency, prevent damage, and ensure safety in their operations.

The wet sensor sensor is a crucial component in various industries, including agriculture, environmental monitoring, and industrial applications. This sensor is designed to detect the presence of moisture or water in a particular environment, providing valuable data for decision-making and control purposes. In this article, we will explore the components and modules that make up a wet sensor sensor, as well as its applications and benefits.

1. Moisture Sensor: The core component of a wet sensor sensor is the moisture sensor itself. This sensor is typically made up of two electrodes that measure the electrical conductivity of the surrounding medium. When moisture or water is present, the conductivity of the medium increases, allowing the sensor to detect the presence of moisture.

2. Microcontroller: The microcontroller is responsible for processing the data collected by the moisture sensor and converting it into a readable format. This component is essential for controlling the sensor's operation and transmitting the data to a monitoring system or display.

3. Transmitter: In some cases, a wet sensor sensor may include a transmitter module that allows the sensor to wirelessly transmit data to a remote monitoring system. This feature is particularly useful in applications where the sensor is located in a hard-to-reach or hazardous environment.

4. Power Supply: A power supply module is required to provide the necessary energy for the sensor to operate. This can be in the form of batteries, solar panels, or a wired power source, depending on the specific requirements of the application.

5. Housing: The housing of the wet sensor sensor is designed to protect the internal components from environmental factors such as moisture, dust, and temperature fluctuations. The housing is typically made of durable materials such as plastic or metal to ensure the sensor's longevity and reliability.

Modules of a Wet Sensor Sensor:

1. Data Logging Module: Some wet sensor sensors may include a data logging module that allows the sensor to store data internally for later retrieval and analysis. This feature is particularly useful in applications where real-time monitoring is not required, or where data transmission is intermittent.

2. Alarm Module: An alarm module can be integrated into a wet sensor sensor to alert users when a certain threshold of moisture or water is detected. This feature is essential in applications where immediate action is required to prevent damage or safety hazards.

3. Calibration Module: A calibration module is used to calibrate the sensor periodically to ensure accurate and reliable measurements. This module allows users to adjust the sensor's sensitivity and accuracy based on the specific requirements of the application.

4. Communication Module: A communication module enables the wet sensor sensor to communicate with other devices or systems, such as a central monitoring station or a smartphone app. This feature allows users to access real-time data and receive alerts remotely.

Applications of Wet Sensor Sensors:

1. Agriculture: Wet sensor sensors are commonly used in agriculture to monitor soil moisture levels and optimize irrigation practices. By accurately measuring the moisture content of the soil, farmers can ensure that crops receive the right amount of water, leading to improved yields and reduced water wastage.

2. Environmental Monitoring: Wet sensor sensors are also used in environmental monitoring applications to track water levels in rivers, lakes, and reservoirs. This data is essential for assessing water quality, predicting floods, and managing water resources effectively.

3. Industrial Applications: In industrial settings, wet sensor sensors are used to detect leaks, spills, and condensation in equipment and facilities. By monitoring moisture levels in critical areas, companies can prevent equipment failures, reduce downtime, and ensure workplace safety.

Benefits of Wet Sensor Sensors:

1. Improved Efficiency: Wet sensor sensors help optimize water usage in agriculture and other industries, leading to cost savings and environmental benefits. By providing real-time data on moisture levels, these sensors enable users to make informed decisions and adjust their practices accordingly.

2. Preventive Maintenance: By detecting moisture or water early on, wet sensor sensors can help prevent equipment failures and costly repairs. This proactive approach to maintenance can extend the lifespan of equipment and reduce downtime, ultimately saving time and money.

3. Remote Monitoring: Wet sensor sensors with wireless communication capabilities allow users to monitor moisture levels from a distance, enabling timely intervention and response. This feature is particularly useful in large-scale operations or remote locations where regular on-site inspections may not be feasible.

In conclusion, the wet sensor sensor is a versatile and essential component in various industries, offering valuable insights into moisture levels and water presence. By understanding the components and modules that make up a wet sensor sensor, as well as its applications and benefits, users can harness the power of this technology to improve efficiency, prevent damage, and ensure safety in their operations.