Position sensors are essential components in a wide range of industries, from automotive to aerospace, robotics to manufacturing. These sensors are used to detect the position of an object or system in relation to a reference point, providing crucial feedback for control and monitoring purposes. There are several popular types of position sensors available on the market, each with its own unique features and applications. In this article, we will explore some of the most common position sensor product types and their uses.

Potentiometers, also known as potentiometric sensors, are one of the oldest and most widely used types of position sensors. They work by measuring the change in resistance as a wiper moves along a resistive element. Potentiometers are simple, cost-effective, and easy to use, making them ideal for applications where precision is not critical. They are commonly used in volume controls, joysticks, and other consumer electronics.

2. Linear Variable Differential Transformers (LVDTs)

LVDTs are highly accurate and reliable position sensors that are commonly used in industrial applications where precise measurements are required. They work by measuring the change in inductance as a core moves along a coil. LVDTs are capable of measuring linear displacement with high resolution and repeatability, making them ideal for applications such as machine tools, robotics, and aerospace.

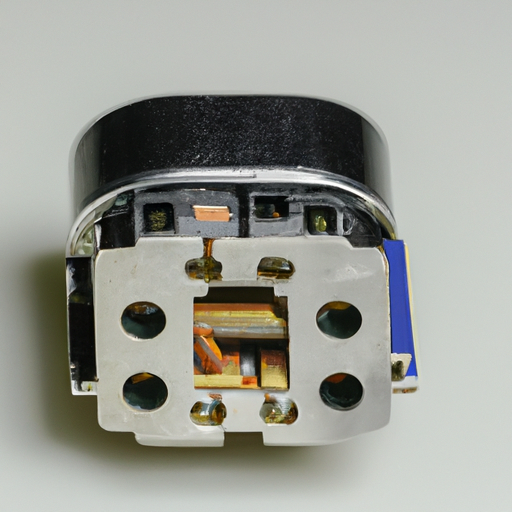

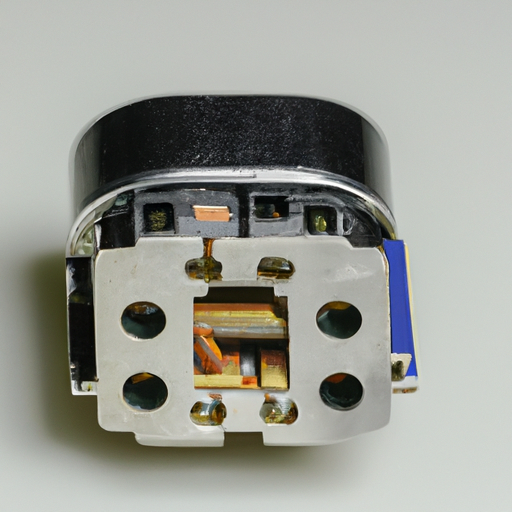

3. Optical Encoders

Optical encoders are position sensors that use light to detect the position of an object. They consist of a light source, a patterned disc, and a photodetector. As the disc rotates, the light passes through the patterned slots, generating a series of pulses that can be used to determine the position of the object. Optical encoders are highly accurate and reliable, making them ideal for applications such as CNC machines, robotics, and medical devices.

4. Hall Effect Sensors

Hall effect sensors are position sensors that use the Hall effect to detect the presence of a magnetic field. They consist of a semiconductor chip with a Hall element that generates a voltage proportional to the strength of the magnetic field. Hall effect sensors are commonly used in automotive applications, such as throttle position sensors and gear position sensors, as well as in industrial applications like position control and speed sensing.

5. Inductive Sensors

Inductive sensors are position sensors that use electromagnetic induction to detect the position of a metallic object. They consist of a coil that generates an electromagnetic field, which is disrupted by the presence of a metallic object. The change in the electromagnetic field is then used to determine the position of the object. Inductive sensors are commonly used in proximity sensors, limit switches, and position control systems.

6. Capacitive Sensors

Capacitive sensors are position sensors that use changes in capacitance to detect the position of an object. They consist of two electrodes separated by a dielectric material, with the capacitance between the electrodes changing as the object moves closer or further away. Capacitive sensors are commonly used in touchscreens, proximity sensors, and level sensing applications.

7. Ultrasonic Sensors

Ultrasonic sensors are position sensors that use ultrasonic waves to detect the position of an object. They emit high-frequency sound waves that bounce off the object and are then detected by a receiver. The time it takes for the sound waves to return is used to calculate the distance to the object. Ultrasonic sensors are commonly used in robotics, parking sensors, and level sensing applications.

In conclusion, position sensors play a crucial role in a wide range of industries, providing essential feedback for control and monitoring purposes. There are several popular types of position sensor product types available on the market, each with its own unique features and applications. Whether you need a simple and cost-effective potentiometer or a highly accurate and reliable LVDT, there is a position sensor to suit your needs. By understanding the different types of position sensors and their uses, you can choose the right sensor for your specific application and ensure optimal performance and reliability.

Position sensors are essential components in a wide range of industries, from automotive to aerospace, robotics to manufacturing. These sensors are used to detect the position of an object or system in relation to a reference point, providing crucial feedback for control and monitoring purposes. There are several popular types of position sensors available on the market, each with its own unique features and applications. In this article, we will explore some of the most common position sensor product types and their uses.

Potentiometers, also known as potentiometric sensors, are one of the oldest and most widely used types of position sensors. They work by measuring the change in resistance as a wiper moves along a resistive element. Potentiometers are simple, cost-effective, and easy to use, making them ideal for applications where precision is not critical. They are commonly used in volume controls, joysticks, and other consumer electronics.

2. Linear Variable Differential Transformers (LVDTs)

LVDTs are highly accurate and reliable position sensors that are commonly used in industrial applications where precise measurements are required. They work by measuring the change in inductance as a core moves along a coil. LVDTs are capable of measuring linear displacement with high resolution and repeatability, making them ideal for applications such as machine tools, robotics, and aerospace.

3. Optical Encoders

Optical encoders are position sensors that use light to detect the position of an object. They consist of a light source, a patterned disc, and a photodetector. As the disc rotates, the light passes through the patterned slots, generating a series of pulses that can be used to determine the position of the object. Optical encoders are highly accurate and reliable, making them ideal for applications such as CNC machines, robotics, and medical devices.

4. Hall Effect Sensors

Hall effect sensors are position sensors that use the Hall effect to detect the presence of a magnetic field. They consist of a semiconductor chip with a Hall element that generates a voltage proportional to the strength of the magnetic field. Hall effect sensors are commonly used in automotive applications, such as throttle position sensors and gear position sensors, as well as in industrial applications like position control and speed sensing.

5. Inductive Sensors

Inductive sensors are position sensors that use electromagnetic induction to detect the position of a metallic object. They consist of a coil that generates an electromagnetic field, which is disrupted by the presence of a metallic object. The change in the electromagnetic field is then used to determine the position of the object. Inductive sensors are commonly used in proximity sensors, limit switches, and position control systems.

6. Capacitive Sensors

Capacitive sensors are position sensors that use changes in capacitance to detect the position of an object. They consist of two electrodes separated by a dielectric material, with the capacitance between the electrodes changing as the object moves closer or further away. Capacitive sensors are commonly used in touchscreens, proximity sensors, and level sensing applications.

7. Ultrasonic Sensors

Ultrasonic sensors are position sensors that use ultrasonic waves to detect the position of an object. They emit high-frequency sound waves that bounce off the object and are then detected by a receiver. The time it takes for the sound waves to return is used to calculate the distance to the object. Ultrasonic sensors are commonly used in robotics, parking sensors, and level sensing applications.

In conclusion, position sensors play a crucial role in a wide range of industries, providing essential feedback for control and monitoring purposes. There are several popular types of position sensor product types available on the market, each with its own unique features and applications. Whether you need a simple and cost-effective potentiometer or a highly accurate and reliable LVDT, there is a position sensor to suit your needs. By understanding the different types of position sensors and their uses, you can choose the right sensor for your specific application and ensure optimal performance and reliability.